When it comes to 3D printing, support structures are crucial for creating complex designs with overhanging features. One popular material for support structures is PVA (polyvinyl alcohol) which is a water-soluble filament.

Known for its ease of use and compatibility with a wide range of 3D printers, PVA filament offers a host of benefits for creating intricate designs with minimal post-processing.

What is PVA water soluble filament?

PVA water-soluble filament is a type of 3D printing material that dissolves in water, making it ideal for creating support structures that can be easily removed without leaving any residue. It is commonly used in conjunction with other filaments to create intricate designs that require temporary scaffolding during the printing process.

Unlike traditional support structures, which can be difficult and time-consuming to remove, PVA dissolves easily in a water bath, leaving behind a clean final product without any risk of damage to delicate features.

PVA eliminates the need for harsh chemicals or specialized tools often required for support removal, making the process simpler and safer. Additionally, PVA boasts good adhesion with PLA, a widely used filament, making it a compatible choice for building supports for PLA prints.

Beyond its role as a support material, PVA offers other desirable properties such as biodegradability, high impact strength, and good dimensional stability. Overall, PVA filament stands out as a user-friendly and versatile material that can significantly enhance the quality and efficiency of 3D printing for complex objects.

Does PVA filament need to be dried?

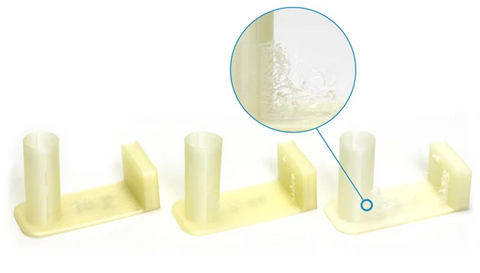

One key aspect to remember when working with PVA filament is its susceptibility to moisture absorption. Unlike some other filaments, PVA is hygroscopic, meaning it readily attracts and retains water vapor from the surrounding environment. This absorbed moisture can significantly impact the quality of your 3D prints. Even a small amount of moisture, exceeding just 2%, can lead to printing issues like unsightly blobbing, filament oozing from the nozzle, crackling sounds during printing, and a noticeable decline in overall print quality.

To avoid these printing frustrations and ensure successful results with PVA, proper storage and drying are crucial. Several filament dryer options are available on the market, including those from reputable brands like Sunlu. These dryers utilize heat and often incorporate desiccant packs to effectively remove moisture from your filament.

By employing a filament dryer, you can restore your PVA filament to its optimal printing condition, ensuring it performs as intended and delivers clean, high-quality prints that showcase the full potential of this unique 3D printing material.

Why PVA water soluble filament is the ideal choice for 3D printing support structures

In conclusion, PVA filament stands out as the near-perfect choice for support structures in 3D printing, particularly when dealing with intricate designs.

Its water solubility eliminates the tedious and potentially damaging process of manual support removal. Simply submerging the print in water dissolves the PVA, leaving behind a pristine final product. Furthermore, PVA boasts environmental benefits with its biodegradability, and its compatibility with PLA, a popular filament choice, makes it a practical solution.

While proper storage and drying are essential due to PVA's hygroscopic nature, the ease of use, safety, and superior results make PVA filament the ideal material for creating complex 3D prints with a professional finish.